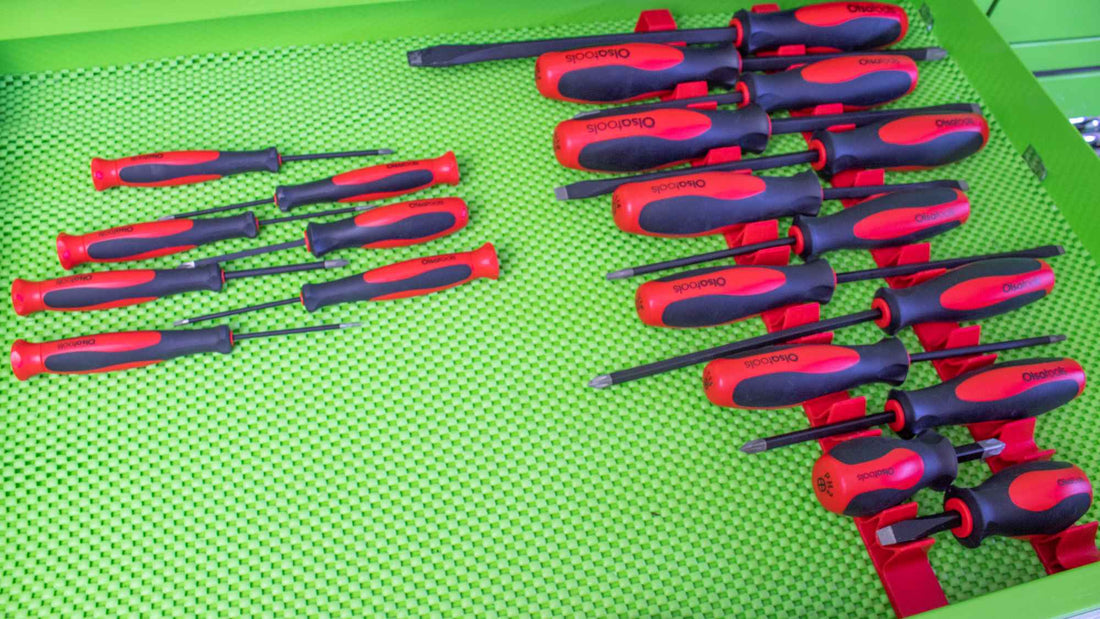

Screwdrivers are oftentimes the first tool we buy when starting a toolkit. Whether you’re a professional mechanic or a DIY enthusiast, these tools come in handy from day one. But just because screwdrivers are foundational doesn’t mean buying them is as simple as walking into the shop and grabbing the first set you see.

We’ll break down screwdriver anatomy, common types, and selection criteria. You'll learn what separates premium screwdrivers from inferior ones, and see why Olsa Tools delivers professional-grade screwdrivers at prices that won't empty your wallet.

Parts of Screwdrivers

A screwdriver is made of three main parts that transfer force from your hand to the screw.

Screwdriver Handle

Screwdriver handles determine your grip, comfort, and torque capability. The right handle choice depends on your specific task requirements.

- Standard composite handles combine a hard plastic core with rubber coating to balance durability and comfort during daily professional use.

- Cushion grip handles feature multiple impact-resistant layers that resist chemicals and oils while providing superior comfort during extended workshop sessions.

- T-handle designs deliver maximum torque for stubborn fasteners and excel in automotive work, though they demand more storage space in your toolbox.

Shaft Options and Applications

The screwdriver shaft transfers torque from the handle to the tip. Your choice of shaft length and profile impacts tool access and power delivery.

- Stubby shafts measure 2–4 inches and provide access in confined spaces and tight corners.

- Standard shafts span 4–8 inches and provide optimal length and leverage for most general tasks.

- Extended shafts run 8–12 inches and reach deep recesses or pass through access holes but sacrifice some torque.

- Round profile shafts suit most general-purpose work with reliable torque transfer.

- Hex profile shafts work with a wrench to multiply torque on particularly stubborn fasteners.

Drive Tip or Bit

The drive tip determines how effectively your screwdriver engages with fasteners. Professional-grade screwdrivers come in two distinct tip styles:

- Fixed-tip screwdrivers feature precision-machined steel tips permanently fused to the shaft, creating unbroken power transfer from handle to tip. This solid construction maximizes torque delivery and withstands heavy daily use in professional settings.

- Detachable bit systems trade some durability for versatility. These screwdrivers accept interchangeable tips to handle multiple fastener types with a single tool.

While the connection point between the shaft and bit introduces a potential weak point, modern quick-change mechanisms have significantly improved their strength and reliability. For DIY users and home mechanics building their first toolkit, detachable tip screwdrivers are cost-effective investments.

Screwdriver Tip and Bits

Centuries of engineering progress and specialized fasteners have produced many screwdriver bits. Here are the most common options:

- Phillips head screwdrivers feature a cross-shaped tip that centers automatically in the screw recess. This self-centering action prevents the tip from slipping off the fastener, though the design intentionally cams out under high torque to prevent overtightening.

- Flat-head (slotted) screwdrivers represent the original drive pattern. Their simple design works well for slotted screws, particularly in restoration work on vintage machinery and furniture. The straight blade works also as a light-duty prying tool and scraper when needed, though this risks damaging the tip.

- Torx screwdrivers use a six-pointed star pattern that maximizes surface contact with the fastener. This increased engagement allows for higher torque transfer without damaging the screw head. Automotive manufacturers frequently specify Torx fasteners for sensitive components where precise torque control matters.

- Robertson (square) drive screwdrivers are used for woodworking projects and construction. The square recess holds fasteners securely on the tip, enabling one-handed operation. This self-retaining feature proves especially valuable when starting screws in awkward positions or overhead work.

- Pozidriv tips look similar to Phillips but include additional smaller notches between the main cross blades. This modification increases torque capacity compared to standard Phillips heads. The design sees widespread use in European machinery and automotive applications.

Different Types of Screwdrivers

Besides the tips and bits, here are some of the screwdriver options you’ll find:

|

Screwdriver type |

Description |

Common uses |

|

Magnetic screwdriver |

Equipped with a magnetic tip to hold screws in place. |

Working in tight spaces, electronics, and automotive repairs. |

|

Precision screwdriver |

Small screwdrivers for delicate, detailed work. |

Watches, eyeglasses, and small electronics. |

|

Insulated screwdriver |

Made of non-conductive materials to protect against electric shocks. |

Electrical work, including circuit installation and repairs. |

|

Allen wrench |

A fixed hex-head screwdriver with a 90-degree bend. |

Bicycle maintenance, furniture assembly, and mechanical repairs. |

|

Ratcheting screwdriver |

Features a ratcheting mechanism for continuous rotation in one direction without repositioning. |

Quick screwdriving tasks in mechanics and assembly work. |

|

Torque screwdriver |

Equipped with a torque-limiting clutch to prevent over-tightening. |

Precision assembly, aerospace, and automotive applications. |

|

Electric screwdriver and impact driver |

Powered screwdrivers that apply rotational force, with impact drivers for high-torque fastening. |

Furniture assembly, DIY projects, and heavy-duty fastening. |

How To Choose a Screwdriver Set

Job Requirements

Your work determines which screwdrivers you'll use most. Think about the projects you work on and the fasteners you’ll encounter. Here are some examples:

- General home repairs require flathead and Phillips screwdrivers in standard sizes.

- Automotive repairs require many screwdriver types, including Torx, hex, and Pozidriv, for interior panels, engine components, and electrical systems.

- Electronics and precision work demand small, specialized screwdrivers like precision Phillips, flathead, and Tri-Wing models.

Build Quality

A good screwdriver should be durable, comfortable to use, and effective for the task at hand. High-quality screwdrivers are made from chrome vanadium steel or other hardened alloys that resist wear and provide long-term reliability. The handle should have an ergonomic, non-slip design to give you a secure grip and reduce hand fatigue during extended use.

Most top brands (like Olsa Tools) stand behind their build quality with lifetime warranties that protect your investment.

Budget

Professional-grade screwdriver sets come in all shapes and price ranges.

- Entry-level fixed-tip sets from reputable manufacturers typically range from $30–$70 and include essential Phillips, flathead, and Torx drivers. These sets serve DIY users well but may wear faster under daily professional use.

- Premium fixed-tip sets with chrome vanadium steel construction and ergonomic handles cost $70–$200. For daily professional work, this durability justifies the higher cost.

- Multi-bit screwdriver sets with interchangeable tips offer an economical starting point at $20–$80.

Olsa Tools delivers professional-grade quality without the premium price tag by selling directly to users. Our Torx screwdriver set features the same chrome vanadium steel construction and precision-machined tips as premium brands but costs significantly less.

Shop Olsa Tools torx screwdrivers.

Screwdriver Set Accessories

After bringing your new screwdriver set home, you should protect it. The right storage system protects your investment and simplifies tool access.

Wall-Mounted Storage

Wall-mounted holders save vertical space with clear visibility of your complete screwdriver set. Standard holders usually fit 10–15 screwdrivers and come with secure mounting hardware.

Olsa Tools' wall mount holder has durable clips for a firm grip on handles, yet releases tools smoothly when needed.

Magnetic Organization

Magnetic organizers can be used on steel toolboxes and work surfaces. Strong magnets lock screwdrivers in position to stop rolling and prevent loss in crowded drawers.

Olsa Tools' magnetic organizer features an industrial-strength magnetic base that maintains its hold even in service vehicles.

Toolbox Solutions

Dedicated toolbox organizer trays shield screwdriver tips and speed up tool selection. Premium trays feature precise compartments for specific handle types to eliminate movement during transport. These systems benefit mechanics who transport their tools between job sites.

Rail Systems

Aluminum organizer rails are a customizable storage solution for any toolbox layout. Olsa Tools' screwdriver rails include sturdy clips that mount securely to the aluminum base. These rails accommodate standard and cushion-grip handles, with individual clips that snap tools in place. The system comes in multiple colors to match existing tool storage.

Clip Organization

Individual screwdriver clips provide flexible organization options for any workspace. Olsa Tools' organizer clips can be mounted directly to pegboards, walls, or custom-built holders.

These professional-grade clips feature a spring-loaded design that grips handles securely but releases easily with one hand. The clips work with most standard screwdriver handles and resist wear from repeated use.

The Best Screwdriver Brands

A high-quality screwdriver set lasts for years and saves money on replacements. Here are some of the brands to shop for:

- Craftsman

- Wiha

- Wera

- Snap-On

- Klein Tools

- Olsa Tools

At Olsa Tools, we build professional-grade screwdrivers without the tool truck markup. And with a limited lifetime warranty, our screwdrivers work as hard as you do—for life.

“Can’t beat the price at all; it’s amazing. The handles feel really good … and turn nice and easy... Magnets are actually pretty strong on their own as well, which is handy. Overall happy with my purchase”

—Seth S. (verified buyer of Torx Screwdriver Set with 12 Pieces, five-star review)

Screwdriver Sets FAQ

What is a multi-bit screwdriver?

A multi-bit screwdriver has a single handle with interchangeable heads, so you can switch between different tip types and sizes. It saves space in your toolbox and works for a range of tasks, from minor home repairs to automotive work. On some models, you’ll also find ratcheting mechanisms for added convenience.

Can you use a magnetic screwdriver on a computer?

A magnetic screwdriver won’t damage your computer’s internal components, but small metal particles can stick to the tip and cause issues. For safety, use a non-magnetic screwdriver when working near sensitive electronic components like hard drives or circuit boards.

What are mini screwdrivers used for?

Mini screwdrivers fit tiny screws in electronics, eyeglasses, and watches. These precision tools feature long, thin shafts with micro-sized tips for delicate repairs in tight spaces.

Do ergonomic handles reduce hand fatigue?

Ergonomic handles distribute force evenly across your palm and fingers. The contoured shape prevents pressure points and muscle strain during extended use, especially when tackling stubborn screws.

When should I use a power screwdriver instead of a manual one?

Power screwdrivers excel at repetitive tasks such as furniture assembly or drywall installation. The electric motor of power tools saves time and energy but lacks the precise control of standard screwdrivers for detailed work.

How do I access screws in hard-to-reach places?

Offset screwdrivers and flexible shaft extensions reach around obstacles. For deep recesses, extra-long shaft screwdrivers provide the needed reach without compromising torque transfer.